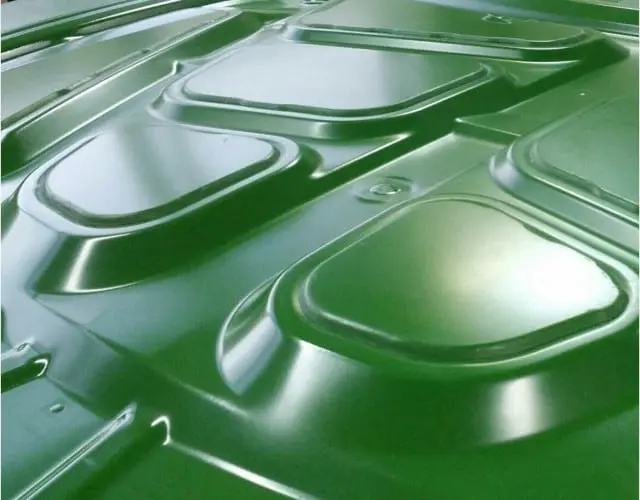

Gelcoats listed in this group,formulated for mould production.High impact,heat and chemical resistance(aging effects of release agent) are main characteristics of these gelcoats.

The product code and some basic properties of the most preferred tooling gelcoats specified in the table below.Please get contact with us for detailed informations of these products and other product types not included in these table.

| Product Description |

|---|

| Isophthalic based chemical resistant type tooling gelcoat |

| Product Description |

|---|

| High HDT,excellent hydrolysis resistant and chemical resistant type tooling gelcoat |

| Product Description |

|---|

| High impact strength, low shrinkage type chemical resistant tooling gelcoat |

| Product Description |

|---|

| ISO/NPG based tooling gelcoat |

| Product Description |

|---|

| High chemical and thermal resistant Bisphenol-A based tooling gelcoat |

| Product Description |

|---|

| Vinyl ester based flame retardant grey colored tooling gelcoat |

| Product Description |

|---|

| Topcoat for mould repair |

| Chemical Structure | Product Description |

|---|---|

| Vinylester | High performance tooling gelcoat |

Tooling Gelcoats - To receive a quote for simply fill out our form and we’ll get in touch with you.

- Request a quote