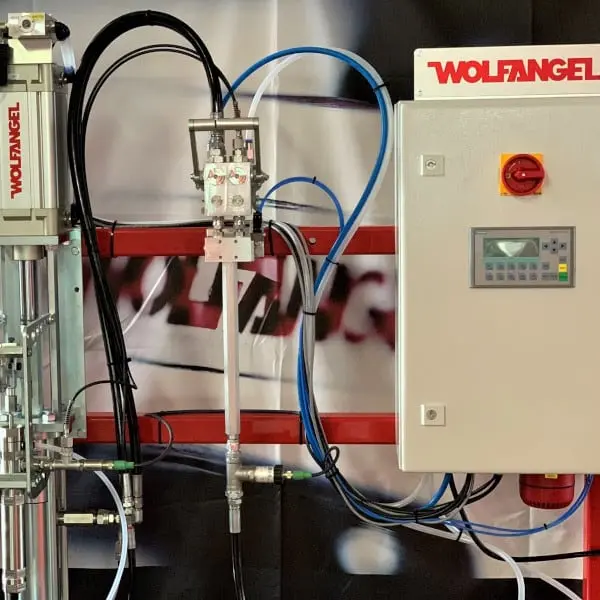

Closed mould injection (RTM) method allow to get both sides smooth and glossy surface proucts. Wolfangel RTM (injection) machines; designed for this kind of applications. It allows to get economical,standart products with classic RTM moulds and it also allows to get products with Light RTM moulds and auxiliary equipments.

Some basic properties of the Wolfangel RTM (injection) machine ,specified in the table below.Please get contact with us for detailed informations of this products and other product types not included in these table.

| Technical Specifications | Values |

|---|---|

| Power | Compressed Air |

| Max. Air Pressure | 6 Bar |

| Air Consumption | 600 l/min |

| Pressure Ratio | 18,5 : 1 |

| Capacity(Depending resin viscosity) | ≈ 4,0 Kg/min |

| Catalyst dosing ratio | 0,7 – 3,4 % |

| Hose Length | 7,5 m |

Wolfangel RTM (injection) Machine - To receive a quote for simply fill out our form and we’ll get in touch with you.

- Request a quote